Precision CNC Parts: The Latest News You Need to Know

By:Admin

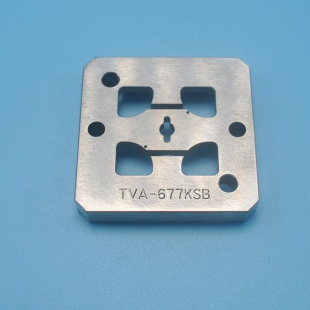

The demand for precision parts continues to rise as industries such as automotive, aerospace, and medical devices require high-precision components for their products. Guansheng's CNC precision parts are designed and manufactured to meet these exacting standards, making them a trusted partner for companies looking for reliable and high-quality components.

The company's CNC precision parts are produced using state-of-the-art machining technology, allowing for the creation of complex and intricate parts with tight tolerances. This level of precision is crucial for industries where safety and performance are paramount, and Guansheng's parts have consistently met and exceeded these requirements.

In addition to their precision manufacturing capabilities, Guansheng also offers a range of materials for their CNC precision parts, including aluminum, stainless steel, and various engineering plastics. This diversity in material options allows for greater flexibility in meeting the specific needs of their clients, ensuring that each part is perfectly suited for its intended application.

Furthermore, Guansheng's commitment to short delivery times sets them apart from their competitors. With their efficient production processes and streamlined supply chain, the company is able to provide quick turnaround times without sacrificing quality. This has made them a preferred supplier for companies that require fast and reliable access to precision parts.

Guansheng's CNC precision parts are also backed by their extensive experience in custom rapid prototyping, mold, and OEM engineering manufacturing. With a focus on innovation and continuous improvement, the company has honed its capabilities to meet the evolving needs of modern industries. Their dedication to staying ahead of the curve has earned them a reputation for being a trusted and forward-thinking manufacturer in the global market.

As the demand for precision parts continues to grow, Xiamen Guansheng Precision Machinery Co., Ltd. stands ready to meet these needs with their exceptional CNC precision parts. With a focus on quality, precision, and efficiency, the company is well-positioned to remain a leader in the industry for years to come.

For companies in search of reliable and high-quality CNC precision parts, Guansheng's offerings are a clear choice. With their combination of advanced technology, skilled team, and commitment to excellence, the company has proven time and again that they are a valuable partner for businesses in need of precision components.

Overall, Xiamen Guansheng Precision Machinery Co., Ltd.'s foray into CNC precision parts further solidifies their position as a leading global manufacturer in the custom rapid prototyping, mold, and OEM engineering manufacturing industry. With their high-quality offerings and dedication to customer satisfaction, it's clear that the company will continue to make an impact in the market for years to come.

Company News & Blog

What You Need to Know About Injection Moulding: A Deep Dive into the Process

Xiamen Guansheng Precision Machinery Co., Ltd. is making waves in the custom rapid prototyping, mold, and OEM engineering manufacturing industry with its cutting-edge injection molding technology. The company, with its headquarters in Xiamen, China, is a well-established and experienced global manufacturer known for its advanced manufacturing technology and highly skilled team. Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold, where it is then cooled and solidified to form the final product. This process is widely used for manufacturing a variety of products, from small components to larger items. With the increasing demand for high-quality injection-molded products, Xiamen Guansheng Precision Machinery Co., Ltd. has positioned itself as a leader in the industry, providing top-notch solutions for its clients.The company's commitment to quality and short delivery times has been the key to its success in the industry. With a strong emphasis on precision and attention to detail, Guansheng has consistently delivered superior products while maintaining an efficient production process. This has earned the company a stellar reputation among its clients and industry peers.Guansheng's injection molding capabilities are backed by state-of-the-art technology and a team of experts who are dedicated to delivering the highest quality products. The company's manufacturing facility is equipped with the latest machinery and equipment, allowing for the production of complex and intricate parts with unparalleled precision. This level of technological sophistication sets Guansheng apart from its competitors and enables the company to meet the diverse needs of its clients.In addition to its advanced manufacturing capabilities, Guansheng also offers comprehensive prototyping and engineering services. The company's experienced team works closely with clients to develop custom solutions that meet their specific requirements. From concept to production, Guansheng provides end-to-end support, ensuring that each project is completed to the highest standards.Guansheng's commitment to quality extends beyond its manufacturing processes. The company places a strong emphasis on sustainability and environmentally friendly practices. By utilizing efficient production methods and minimizing waste, Guansheng is dedicated to reducing its environmental impact while still delivering exceptional products to its clients.As a global leader in the industry, Guansheng has established a strong network of clients and partners around the world. The company's ability to adapt to the ever-changing needs of the market has allowed it to build long-lasting relationships with clients from a wide range of industries, including automotive, aerospace, electronics, and consumer goods.With a dedication to innovation and continuous improvement, Xiamen Guansheng Precision Machinery Co., Ltd. is well-positioned to maintain its leading role in the injection molding and manufacturing industry. The company's focus on quality, efficiency, and customer satisfaction sets it apart as a reliable and trusted partner for businesses seeking top-tier manufacturing solutions.In conclusion, Xiamen Guansheng Precision Machinery Co., Ltd. continues to raise the bar in the custom rapid prototyping, mold, and OEM engineering manufacturing industry with its advanced injection molding technology and commitment to excellence. With its state-of-the-art facilities, skilled team, and dedication to quality, the company is poised to continue delivering innovative and high-quality solutions to clients around the world.

Innovative 3D Prototypes: Revolutionizing Product Development

3D Prototypes Revolutionize Product Development at Leading CompanyIn today's rapidly evolving business landscape, companies are constantly seeking new and innovative ways to stay ahead of the competition. One area that has seen tremendous advancement in recent years is the field of 3D printing and prototyping. At the forefront of this technological revolution is [Company Name], a leading provider of cutting-edge 3D printing solutions.[Company Name] has been at the forefront of 3D printing technology for over a decade, continually pushing the boundaries of what is possible with this groundbreaking technology. Their advanced 3D printers and prototyping capabilities have revolutionized the way companies design and develop new products, streamlining the manufacturing process and reducing time-to-market.The company's state-of-the-art 3D printers are capable of producing high-quality prototypes with incredible precision and accuracy, allowing clients to visualize and test their designs in ways that were previously impossible. From concept to prototype, [Company Name] provides a full range of 3D printing services, enabling companies to bring their ideas to life in ways they never thought possible.With [Company Name]'s industry-leading 3D printing technology, clients can rapidly iterate and refine their designs, significantly reducing the time and cost of product development. This level of flexibility and efficiency has enabled companies to revolutionize their product development processes, ultimately leading to the creation of more innovative and high-quality products.One of the key advantages of 3D printing is the ability to produce complex geometries and intricate designs that would be extremely difficult, if not impossible, to manufacture using traditional methods. This has opened up new possibilities for product designers and engineers, allowing them to push the boundaries of what is achievable with their designs.In addition to the production of prototypes, [Company Name] also offers a range of other 3D printing services, including rapid tooling, low-volume manufacturing, and custom part production. This comprehensive suite of offerings has positioned [Company Name] as a one-stop-shop for all of their clients' 3D printing needs.In a recent interview, [Company Name]'s CEO, [CEO Name], highlighted the impact that their 3D printing technology is having on the industry. "We are proud to be at the forefront of the 3D printing revolution, and we are constantly pushing the boundaries of what is possible with this incredible technology," he said. "Our advanced 3D printing capabilities are enabling our clients to accelerate their product development processes and bring new and innovative products to market faster than ever before."The impact of [Company Name]'s 3D printing technology is being felt across a wide range of industries, from automotive and aerospace to consumer electronics and healthcare. By providing companies with the tools they need to bring their ideas to life in ways that were previously unimaginable, [Company Name] is helping to drive innovation and progress across the board.As the demand for 3D printing and prototyping continues to grow, [Company Name] is well-positioned to remain at the forefront of this rapidly expanding industry. With their advanced technology, unmatched expertise, and commitment to pushing the boundaries of what is possible, [Company Name] will continue to revolutionize product development for years to come.

What You Need to Know About Custom Injection Moulding

Xiamen Guansheng Precision Machinery Co., Ltd. has been making waves in the custom injection moulding industry with its advanced manufacturing technology and highly skilled team. The company, which specializes in custom rapid prototyping, mold and OEM engineering manufacturing, has maintained a strong competitive advantage with its commitment to quality and quick delivery times.With the global demand for custom injection moulding on the rise, Xiamen Guansheng Precision Machinery Co., Ltd. has positioned itself as a leader in the industry. The company's dedication to providing high-quality products and services has earned it a sterling reputation among its clients and peers.One of the key factors that sets Xiamen Guansheng Precision Machinery Co., Ltd. apart from its competitors is its state-of-the-art manufacturing technology. The company constantly invests in the latest machinery and equipment to ensure that it can meet the evolving needs of the market. This commitment to innovation allows Xiamen Guansheng Precision Machinery Co., Ltd. to produce custom injection moulding products that are of the highest quality and built to last.In addition to its cutting-edge technology, Xiamen Guansheng Precision Machinery Co., Ltd. boasts a highly skilled and experienced team. The company's employees are experts in their field and are dedicated to delivering exceptional results for every project. Whether it's a custom rapid prototyping job or a complex OEM engineering manufacturing task, the team at Xiamen Guansheng Precision Machinery Co., Ltd. has the expertise and dedication to get the job done right.Furthermore, Xiamen Guansheng Precision Machinery Co., Ltd. has always prioritized quality and customer satisfaction. The company understands that its clients rely on its services to bring their ideas to life, and it takes this responsibility seriously. By upholding the highest standards of quality control and rigorous testing procedures, Xiamen Guansheng Precision Machinery Co., Ltd. ensures that every custom injection moulding product that leaves its facilities meets or exceeds customer expectations.Moreover, Xiamen Guansheng Precision Machinery Co., Ltd. has set itself apart from the competition by its commitment to short delivery times. The company understands that time is of the essence in the fast-paced world of manufacturing, and it has optimized its processes to minimize lead times without compromising quality. This dedication to efficiency and timeliness has earned Xiamen Guansheng Precision Machinery Co., Ltd. praise from its clients, who rely on the company to deliver their custom injection moulding projects on time, every time.As the demand for custom injection moulding continues to grow, Xiamen Guansheng Precision Machinery Co., Ltd. is well-positioned to meet the needs of the market. With its advanced manufacturing technology, highly skilled team, commitment to quality, and short delivery times, the company has solidified its reputation as a leader in the industry. Whether it's a small rapid prototyping job or a large-scale OEM engineering manufacturing project, clients can trust Xiamen Guansheng Precision Machinery Co., Ltd. to deliver exceptional results every time.

Quality Molding Tooling in China: A Complete Guide

China Molding Tooling is a leading manufacturer of high-quality mold making and injection molding tools. The company has been serving the automotive, medical, consumer goods, and electronics industries for more than 20 years, providing innovative and cost-effective solutions for their customers.The company's state-of-the-art manufacturing facilities are equipped with advanced CNC machines, EDM machines, wire cutting machines, and other precision machining equipment. This allows China Molding Tooling to produce high-precision molds that meet the most stringent quality standards.In addition to manufacturing mold making and injection molding tools, China Molding Tooling also offers a wide range of services, including product design, prototyping, and low-volume production. This comprehensive approach allows the company to provide its customers with end-to-end solutions, from concept to production.China Molding Tooling's team of experienced engineers and technicians are dedicated to delivering the highest quality products and services to their customers. They work closely with each client to understand their specific needs and requirements, ensuring that the final product meets or exceeds their expectations.The company's commitment to quality and customer satisfaction has earned them a solid reputation in the industry. They have successfully completed projects for major international brands and have consistently received positive feedback and referrals from their satisfied clients.In order to stay ahead of the competition, China Molding Tooling is constantly investing in research and development, as well as in the latest technology and machinery. This allows them to offer cutting-edge solutions to their customers and to take on projects of increasing complexity and scale.One of the key strengths of China Molding Tooling is its ability to provide cost-effective solutions without compromising on quality. The company carefully manages its production processes and supply chain to keep costs low, while still delivering products that meet the highest standards.China Molding Tooling is also committed to sustainability and environmental responsibility. They have implemented energy-efficient practices and have adopted green technologies in their manufacturing processes, minimizing the impact on the environment.As part of its ongoing commitment to excellence, China Molding Tooling is continuously improving its operations and expanding its capabilities. The company recently announced a significant expansion of its manufacturing facilities, which will allow them to take on larger and more complex projects, as well as to increase their capacity and efficiency.The expansion will also create new job opportunities in the local community and contribute to the growth of the manufacturing sector in the region. China Molding Tooling is dedicated to supporting economic development and creating a positive impact on the communities in which it operates.The company's vision is to continue to be a global leader in mold making and injection molding tools, while maintaining its focus on quality, innovation, and customer satisfaction. With its strong track record and ongoing investment in technology and talent, China Molding Tooling is well positioned to achieve this vision and to continue to be a trusted partner for its customers.

Discover the latest advancements in mold texturing techniques

Xiamen Guansheng Precision Machinery Co., Ltd. is making waves in the global custom rapid prototyping, mold, and OEM engineering manufacturing industry with their innovative mold textures. The company, known for its advanced manufacturing technology and highly skilled team, is maintaining a competitive edge in terms of quality and delivery time.Mold textures are a crucial element in the manufacturing process, as they give the final product its desired surface finish. Guansheng's mold textures are designed to meet the various needs and specifications of their clients, ensuring that the final product meets and exceeds expectations.With years of experience in the industry, Xiamen Guansheng Precision Machinery Co., Ltd. has developed a deep understanding of the importance of mold textures in the manufacturing process. Their team of experts works closely with clients to understand their specific requirements and to develop textures that are tailored to their needs. This personalized approach sets Guansheng apart from its competitors and has earned the company a reputation for delivering top-notch products.The company's commitment to quality is evident in every aspect of their operations. From the selection of materials to the manufacturing process, Guansheng adheres to the highest standards to ensure that their products meet the strictest of specifications. This dedication to quality has made them a preferred partner for clients around the world.In addition to their commitment to quality, Guansheng also takes pride in their ability to deliver products on a short lead time. Their efficient manufacturing processes and advanced technology allow them to minimize production time without compromising on quality. This ensures that clients receive their products in a timely manner, allowing them to meet their own production deadlines.Guansheng's innovative mold textures have been the key to their success in the custom rapid prototyping, mold, and OEM engineering manufacturing industry. By offering a wide range of textures and finishes, the company has been able to cater to the diverse needs of their clients and provide solutions that are both functional and aesthetically pleasing.While the company's mold textures have been well-received in the market, they continue to push the boundaries of innovation. Guansheng's research and development team is constantly exploring new textures and finishes to offer their clients even more options. This commitment to innovation ensures that the company remains at the forefront of the industry and continues to meet the evolving needs of their clients.As Xiamen Guansheng Precision Machinery Co., Ltd. continues to expand its global presence, their mold textures are expected to play a key role in their growth. With a focus on quality, innovation, and customer satisfaction, the company is well-positioned to solidify its position as a leader in the custom rapid prototyping, mold, and OEM engineering manufacturing industry.In conclusion, Xiamen Guansheng Precision Machinery Co., Ltd. is making waves in the industry with its innovative mold textures. Their commitment to quality, efficiency, and innovation has earned them a reputation as a trusted partner for clients around the world. As the company continues to expand its global presence, their mold textures are expected to play a key role in their success. With a dedicated team of experts and a focus on meeting the diverse needs of their clients, Guansheng is well-positioned to maintain its competitive edge and continue to lead the way in the industry.

High-Quality Custom Cnc Milling Services for Metals

Custom CNC Milling Metals: Bringing Precision Manufacturing to the Next LevelIn the world of manufacturing, precision is key. It is crucial for companies to have access to high-quality machining services that can produce precise and accurate components. This is where Custom CNC Milling Metals comes in.Custom CNC Milling Metals is a leading provider of custom CNC milling services for a wide range of industries. With state-of-the-art equipment and a team of skilled machinists, they are able to produce complex and intricate parts with unmatched precision and accuracy. Their commitment to quality and attention to detail has made them a trusted partner for many companies seeking high-quality machining solutions.With a focus on continuous improvement and innovation, Custom CNC Milling Metals has invested in the latest CNC milling technology to ensure that they can meet the evolving needs of their clients. Their modern facility is equipped with a range of CNC milling machines, including 3-axis, 4-axis, and 5-axis machines, as well as advanced CAD/CAM software for design and programming.One of the key advantages of Custom CNC Milling Metals is their ability to work with a wide variety of materials. From aluminum and stainless steel to titanium and exotic alloys, they have the expertise and capabilities to machine a diverse range of metals to exact specifications. This versatility makes them an ideal choice for companies in aerospace, automotive, medical, and other high-tech industries where precision and quality are non-negotiable.Furthermore, Custom CNC Milling Metals prides itself on its flexibility and quick turnaround times. Whether a client needs a small batch of parts or a large production run, they are able to accommodate a wide range of order sizes while maintaining the same high level of precision and quality. This makes them a reliable partner for companies with varying production needs and timelines.In addition to their machining capabilities, Custom CNC Milling Metals also offers a range of secondary services to provide a complete solution for their clients. This includes finishing services such as anodizing, plating, and powder coating, as well as assembly and inspection services to ensure that the final product meets the highest standards.Custom CNC Milling Metals understands that every project is unique, and they work closely with their clients to understand their specific requirements and deliver tailor-made solutions. Their team of experienced engineers and machinists are committed to providing the highest level of customer service and technical support throughout the entire process, from initial consultation to final delivery.With a dedication to quality, precision, and customer satisfaction, Custom CNC Milling Metals has established itself as a leader in the CNC milling industry. Their state-of-the-art facility, skilled workforce, and commitment to innovation make them the go-to choice for companies looking for reliable and high-quality machining solutions.As the demand for precision-engineered components continues to grow, Custom CNC Milling Metals is well-positioned to meet the needs of the industry. With a focus on continuous improvement and customer satisfaction, they are primed to remain a trusted partner for companies seeking top-notch CNC milling services. Whether it's a simple prototype or a complex production run, customers can rely on Custom CNC Milling Metals to deliver precision manufacturing at its finest.

Guide to Understanding How CNC Machines Work

CNC MACHINE WORKING: Revolutionizing Manufacturing ProcessesWith the advancements in technology, manufacturing processes have significantly evolved over the years. One of the most noteworthy developments in the manufacturing industry is the introduction of Computer Numerical Control (CNC) machines. These machines have revolutionized the way products are manufactured, allowing for greater precision, efficiency, and automation in the production process.[Company Name] is at the forefront of this revolution, providing state-of-the-art CNC machines to various industries across the globe. The company prides itself on its cutting-edge technology and innovative solutions, catering to the diverse needs of its clients. With a strong focus on quality and reliability, [Company Name] has established itself as a leading provider of CNC machines, offering a wide range of products to suit different manufacturing requirements.CNC machines work by using computerized systems to control the movement and operation of cutting and shaping tools. These machines are capable of producing intricate and complex parts with high accuracy and repeatability. This level of precision is extremely valuable in industries such as aerospace, automotive, medical, and electronics, where the demand for high-quality components is paramount.One of the key advantages of CNC machines is their ability to automate the manufacturing process, reducing the need for manual intervention and human error. This not only improves the overall efficiency of the production process but also allows for faster turnaround times and increased productivity. Furthermore, CNC machines can be programmed to perform a wide range of tasks, making them incredibly versatile and adaptable to various manufacturing needs.[Company Name]’s CNC machines are equipped with advanced features and capabilities, making them suitable for a wide range of applications. Whether it's milling, turning, drilling, or grinding, their machines are designed to deliver outstanding performance and reliability. The company also provides comprehensive training and support to ensure that their clients can maximize the potential of their CNC machines.In addition to their cutting-edge technology, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. Their CNC machines are designed to minimize waste and optimize resource utilization, aligning with the global efforts towards a greener and more sustainable future.The impact of CNC machines on the manufacturing industry cannot be overstated. These advanced technologies have not only improved the quality and precision of manufactured products but have also led to significant cost savings and enhanced competitiveness for businesses. With the continuous innovation and development of CNC machines, the manufacturing industry is poised to achieve new levels of efficiency and productivity.As the demand for high-quality, precision-engineered products continues to grow, the role of CNC machines in shaping the future of manufacturing becomes even more crucial. Companies like [Company Name] are at the forefront of this revolution, driving innovation and setting new industry standards.In conclusion, CNC machines have undoubtedly transformed the manufacturing landscape, offering unprecedented levels of precision, efficiency, and automation. Through their cutting-edge technology and unwavering commitment to quality, [Company Name] has positioned itself as a leading provider of CNC machines, empowering businesses to thrive in a highly competitive market. As the manufacturing industry continues to evolve, the significance of CNC machines in driving progress and advancement cannot be overlooked.

Advanced CNC Prototyping Machine for Custom Manufacturing

Custom CNC Prototyping MachineCustom CNC prototyping machines are the latest innovation in the manufacturing industry. These machines are designed to produce high-quality and precise prototypes with a faster turnaround time. The development of custom CNC prototyping machines has significantly advanced the manufacturing process, allowing companies to create prototypes of their products and parts for testing and evaluation.These custom machines have been developed and manufactured by a leading company in the industry. With years of experience and expertise in the field of CNC machining, the company has been at the forefront of innovation, consistently developing advanced manufacturing technologies to meet the growing demands of the industry. The latest addition to their product line, custom CNC prototyping machines, is another milestone in their quest for excellence.The custom CNC prototyping machines are designed to provide exceptional accuracy and repeatability, ensuring that the prototypes produced meet the highest quality standards. These machines are equipped with advanced software and controls, allowing for precise and intricate machining operations. The result is prototypes that mirror the exact specifications and design requirements of the final product, enabling companies to make informed decisions about their products before mass production.The custom CNC prototyping machines offer a wide range of capabilities, including 3-axis, 4-axis, and 5-axis machining, allowing for complex geometries and intricate designs to be produced with ease. The machines are also compatible with a variety of materials, from metals to plastics, ensuring that companies can create prototypes for a diverse range of products and parts. Moreover, the machines are equipped with automated tool changers and coolant systems, streamlining the manufacturing process and reducing production time.In addition to their advanced capabilities, the custom CNC prototyping machines are also designed with user-friendly interfaces, making them accessible to a wide range of operators and technicians. The intuitive controls and programming interface allow for easy setup and operation, minimizing the learning curve for users. This makes the machines an ideal choice for companies looking to integrate advanced prototyping capabilities into their manufacturing processes.Furthermore, the company provides comprehensive training and support for their custom CNC prototyping machines. Their team of expert technicians and engineers are available to assist customers with installation, setup, and maintenance, ensuring that the machines perform optimally and reliably. This commitment to customer support reflects the company's dedication to delivering value and excellence to their clients.The custom CNC prototyping machines have already garnered attention from various industries, including aerospace, automotive, medical, and consumer goods. Companies within these sectors are embracing the advanced capabilities of these machines to accelerate their product development processes, reduce time to market, and improve the overall quality of their products.As the manufacturing industry continues to evolve, the demand for advanced prototyping capabilities is only expected to grow. Custom CNC prototyping machines offer companies the ability to stay ahead of the competition and achieve greater efficiencies in their product development and manufacturing processes. With the expertise and support of a leading company in the industry, these machines are set to revolutionize the way companies approach prototyping and product development.

High-Quality Custom Vacuum Casting Services at Competitive Prices

Xiamen Guansheng Precision Machinery Co., Ltd. is making waves in the manufacturing industry with its custom vacuum casting solutions, providing high-quality rapid prototyping, mold, and OEM engineering manufacturing services to clients worldwide.Custom vacuum casting, also known as urethane casting, is a manufacturing process that is used to produce high-quality prototypes and low-volume production parts. It is particularly well-suited for applications where a high level of detail and surface finish is required, making it a popular choice for industries such as automotive, aerospace, medical, and consumer goods.Guansheng's custom vacuum casting process involves the use of a silicone mold to create parts from a wide range of materials, including polyurethane resins, rubber-like materials, and clear plastics. This process allows for the production of parts with complex geometries and intricate details, making it an ideal solution for prototyping and low-volume production runs.The company's advanced manufacturing technology and highly skilled team enable them to offer a wide range of custom vacuum casting services, including rapid prototyping, mold design and fabrication, and OEM engineering manufacturing. With a focus on quality and efficiency, Guansheng is able to provide its clients with short delivery times and cost-effective solutions, making it a preferred partner for businesses looking to bring their products to market quickly and affordably.In addition to custom vacuum casting, Guansheng also offers a range of other manufacturing services, including CNC machining, 3D printing, injection molding, and metal casting. This comprehensive suite of capabilities allows the company to meet the diverse needs of its clients, providing them with a one-stop solution for all their manufacturing requirements.Customers who have worked with Guansheng have consistently praised the company for its attention to detail, quality craftsmanship, and commitment to customer satisfaction. By leveraging its expertise in custom vacuum casting and other manufacturing processes, Guansheng has been able to help its clients bring their innovative ideas to life, turning concepts into reality with speed and precision.One of the key advantages of custom vacuum casting is its ability to produce high-quality parts at a fraction of the cost of traditional manufacturing methods. This makes it a cost-effective solution for businesses looking to prototype new designs or produce low-volume production runs without breaking the bank.Guansheng's custom vacuum casting process also offers a high degree of flexibility, allowing for the production of parts in a wide range of materials, colors, and surface finishes. This makes it possible for clients to create prototypes that closely mimic the look and feel of the final product, helping them to make informed decisions about design and functionality before committing to mass production.With its commitment to quality, efficiency, and customer satisfaction, Xiamen Guansheng Precision Machinery Co., Ltd. has solidified its reputation as a leading provider of custom rapid prototyping, mold, and OEM engineering manufacturing services. By harnessing the power of custom vacuum casting and other advanced manufacturing processes, the company continues to help businesses around the world bring their ideas to life with speed, precision, and cost-effectiveness.

High-Quality Small Batch CNC Machining Services

Xiamen Guansheng Precision Machinery Co., Ltd. has established itself as a leader in the global custom rapid prototyping, mold, and OEM engineering manufacturing industry. With a focus on advanced manufacturing technology and a highly skilled team, the company has maintained a competitive advantage with its commitment to quality and short delivery times. One area where Guansheng excels is in small batch CNC machining, a service that has set it apart from others in the industry.Small batch CNC machining is a specialized service that allows for the production of a small number of parts or components with high precision and accuracy. This process is ideal for companies or individuals looking to create prototypes or test designs before moving into full-scale production. Guansheng's small batch CNC machining service is known for its reliability, efficiency, and attention to detail, making it a popular choice among clients looking for high-quality components in limited quantities.The small batch CNC machining process at Guansheng begins with the initial design phase, where their team of engineers works closely with clients to understand their specific requirements and expectations. Once the designs are finalized, the company's state-of-the-art CNC machines are programmed to create the parts with the utmost precision. The use of advanced CNC technology ensures that each component meets the exact specifications provided by the client, resulting in a final product that is both accurate and consistent.One of the key advantages of Guansheng's small batch CNC machining service is its ability to produce complex and intricate parts with tight tolerances. This level of precision is essential for industries such as aerospace, automotive, and medical, where even the smallest deviation can have significant consequences. The company's commitment to quality and precision has earned it a reputation as a trusted provider of small batch CNC machining services for a wide range of applications.In addition to its technical capabilities, Guansheng also places a strong emphasis on efficient production and short lead times. The company understands the importance of delivering parts within tight deadlines, especially for clients working on time-sensitive projects. By streamlining its manufacturing processes and leveraging its expertise in CNC machining, Guansheng is able to meet the demands of clients requiring small batch production with tight turnaround times.Furthermore, Guansheng's small batch CNC machining service is backed by a team of skilled technicians and quality control professionals who ensure that each part meets the company's strict standards. This dedication to quality assurance has earned the trust and satisfaction of clients around the world, resulting in long-term partnerships and repeat business.With a strong focus on customer satisfaction and a commitment to excellence, Xiamen Guansheng Precision Machinery Co., Ltd. continues to lead the way in small batch CNC machining and other manufacturing services. The combination of advanced technology, highly skilled personnel, and a customer-centric approach has positioned the company as a top choice for clients seeking reliable and high-quality manufacturing solutions.As the manufacturing industry continues to evolve, Guansheng remains dedicated to staying at the forefront of innovation, always seeking new ways to improve its processes and expand its capabilities. With a growing demand for small batch production solutions, the company is well-positioned to meet the needs of clients across various industries and sectors.In conclusion, Xiamen Guansheng Precision Machinery Co., Ltd. has established itself as a reputable and reliable provider of small batch CNC machining services, catering to clients with diverse needs and requirements. With a focus on quality, precision, and efficiency, the company continues to set the standard for manufacturing excellence in today's competitive market.